Tool & Die

for more precision.

Our know-how in the production of complex components is also demonstrated by the development and manufacture of high-precision vertical 5‑axis milling centres for tool and die industry.

Through configurable options packages and customized automation and technology solutions, the machines for tool and die ensure the individual competitive advantage of our customers. Thanks to the newly developed additionally turning functionality, the range of application for flexible complete machining is considerably extended. A very wide range of workpieces can also be machined with a maximum workpiece diameter of 1500mm.

Some examples of workpieces

We develop machines for your individual and complex workpieces. Here you can see three typical examples of workpieces for this branch.

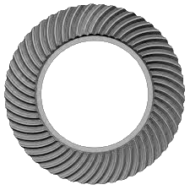

Propeller

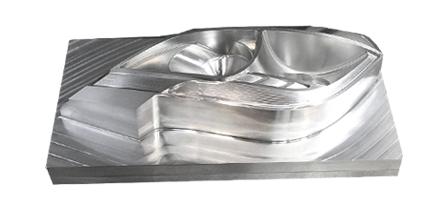

Injection mould