HEGENSCHEIDT MFD: Longer lifetime for bearing rings due hard rolling

News from our sister HEGENSCHEIDT from Erkelenz

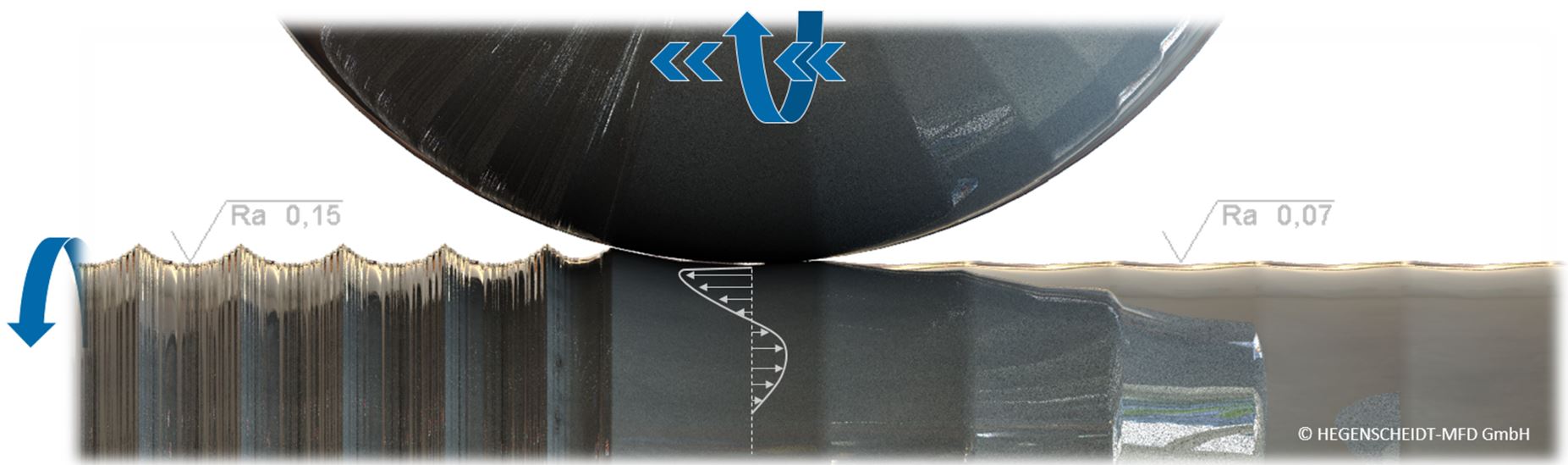

Roller bearings guide shafts and axles, for example in vehicles, industrial plants or medical technology applications. Usually such bearings run permanently under high loads. Material fatigue and lubrication defect are therefore the main causes of component failure. High performance roller bearings can be manufactured with ceramic elements combined with bearing steel. For the production of bearing rings, the Fraunhofer Institute for Production Technology IPT Aachen successfully tested hard rolling as a resource-saving alternative to extending the conventional process chain together with three project partners, including Hegenscheidt-MFD GmbH in Erkelenz.

In the three-year research project, the Fraunhofer IPT, together with the project partners Cerobear GmbH, Hegenscheidt-MFD GmbH and Schmitz-Metallographie GmbH, showed that the bearing rings achieve a significantly longer life as a result of the process sequence of hard turning and hard rolling with a newly developed hard rolling tool. Hard rolling thus offers a resource-saving alternative to the conventional process chain for hard machining, which is also more cost-effective. The longer bearing lifetime contributes to a further increase in efficiency and therefore reduces costs not only for manufacturer but also for the operators.

More information on www.hegenscheidt-mfd.com.