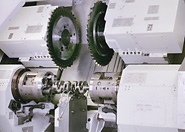

CRANKSHAFT TURN-BROACHING N20 TB | N30 TB

The NILES-SIMMONS Crankshaft Turn-Broaching Machines N20 TB and N30 TB are based on the modular building-block system of the N‑series. Two symmetrically arranged tool spindles with powerful and electronically synchronized spindle drives and two mirror imaged broaching units with highly dynamic rotary axes to locate the tool discs ensure efficient turning and turn-broaching operations on crankshaft bearings and other concentric features of crankshafts. The use of maximum 2x48 tool pockets to locate the reversible cutting inserts ensures high flexibility and long tool life due to the use of sister tools.

Added value:

- 2 symmetrical, temperature controlled motor spindle drives with excellent power and torque parameters

- Rapid positioning of cutting tools by means of highly dynamic rotary axes

- Simultaneous operation of both tool disks with independent feed rates

- Adaptable clamping solutions with shaft chucks to machine flange and post in one setup

- Semi-automatic tool clamping, automatic transfer of pre-set tool data via ID-chip

Technical data

| Turn Broaching TB | |||

| Specification | N20 TB | N30 TB | |

| Working area | |||

| Nominal length | mm | 1000 / 1500 | 1500 / 2000 / 2500 |

| Swing over cross slide guide | mm | 650 | 780 |

| Tool length, max. | mm | 500 / 850 | 800 / 1300 / 1800 |

| Main spindle and counter | |||

| Work spindle nose acc.to DIN 550266 | size | A8 | A11 |

| Work spindle bore | mm | 92 | 92 |

| Spindle diameter in front bearing | mm | 150 | 180 |

| Drive power 100% / 60% duty cycle | kW | 2 x 31 / 35 | 2 x 64 / 78 |

| Speed range | rpm | 2500 | 3000 |

| LH and RH tool drive unit | |||

| Rapid feed cross / longitudinal | m/min | 30 / 40 | 18 / 30 |

| LH and RH tool system | |||

| Tool acceptance | DIN 55026 | A11 | A11 |

| Tool diameter | mm | 700 | 700 (800) |

| Pockets | number | 45 / 48 | 45 / 48 |