Feedback from our Customers

We invite you – to the EMO in Hannover

From 18.09.23 to 23.09.23 we will present our technology highlights in Hall 13 at booth B02: a NILES-SIMMONS turn-mill machining center, a RASOMA vertical turning center and our digital highlight: ironMIND©. With our in-house developed condition monitoring system you can keep track of all your machines with the help of a simple and clear operation. Of course, as always, there will also be updates on our WEMA-GLAUCHAU and HEGENSCHEIDT-MFD brands.

Free tickets are available here.

We are looking forward to your visit.

AMB Stuttgart 2024

Dear customers, business partners and mechanical engineering friends,

The time has come again and the AMB opens its doors from 10.09. – 14.09.24 at the Messe Stuttgart.

We will be there again and look forward to welcoming you in hall 4 at stand B11.

You can find more information about our highlights and free trade fair tickets here.

Sample of our Technologies

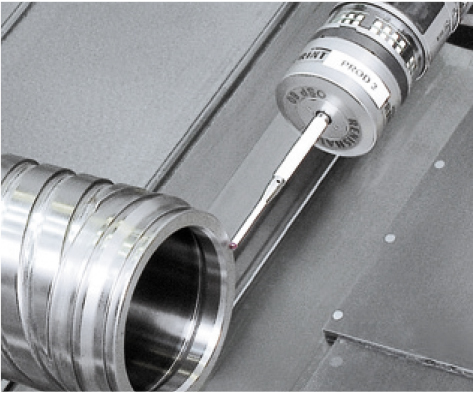

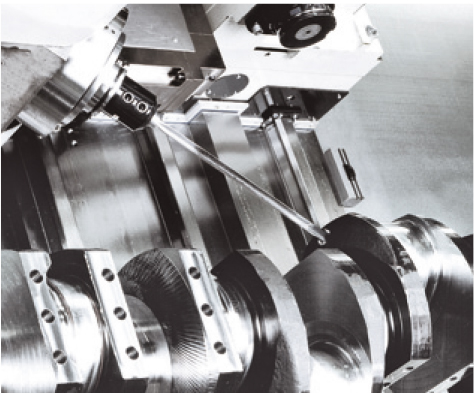

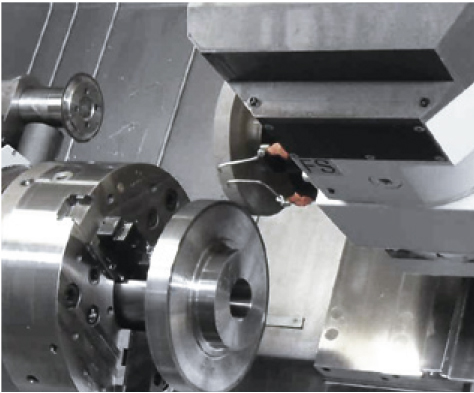

Turning

Drilling

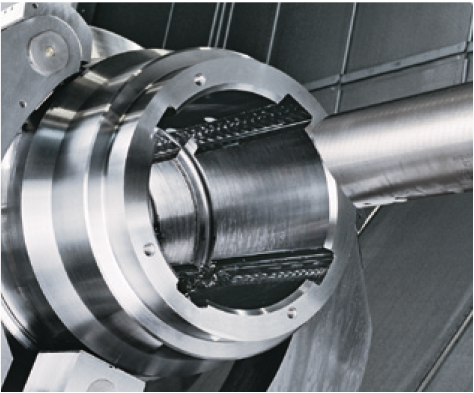

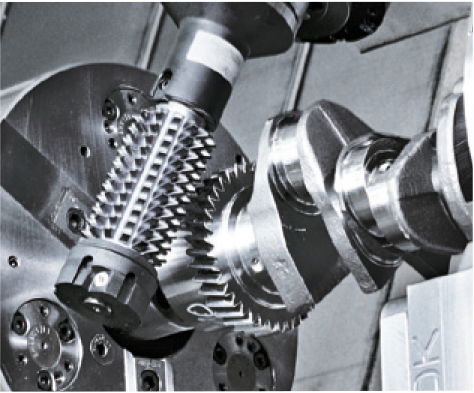

Hobbing

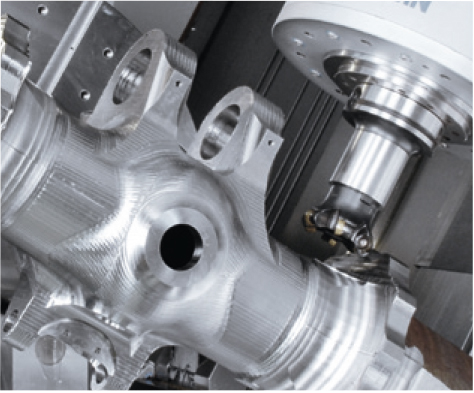

5‑Axis Machining

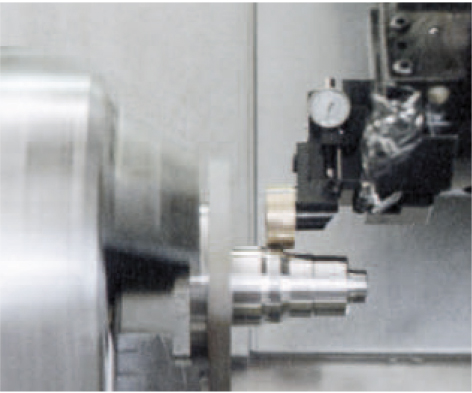

Grinding

Our Service worldwide

Our 5 industrial branches with selected workpieces

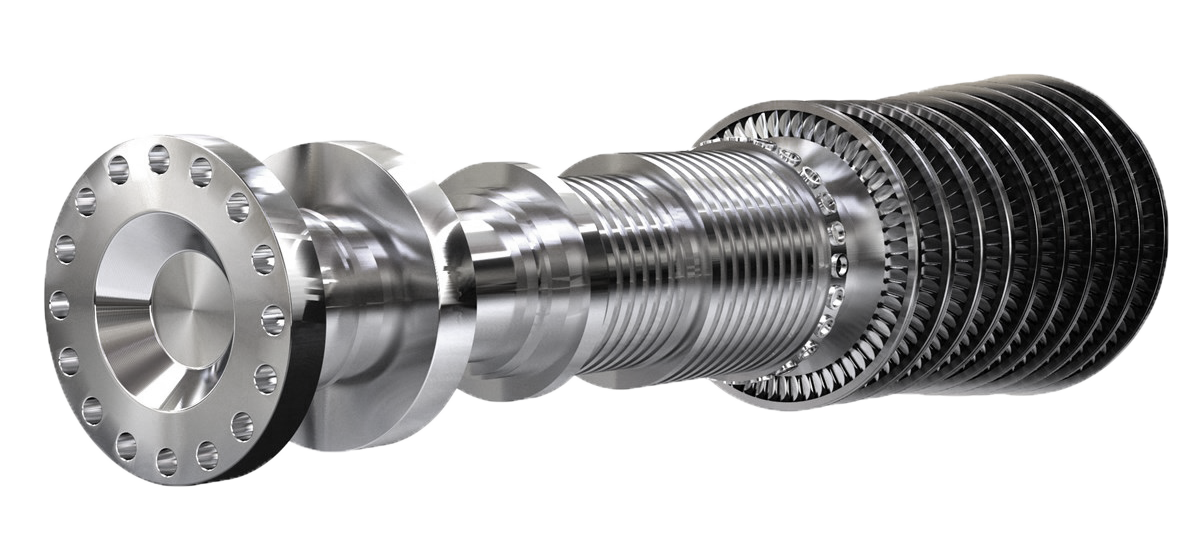

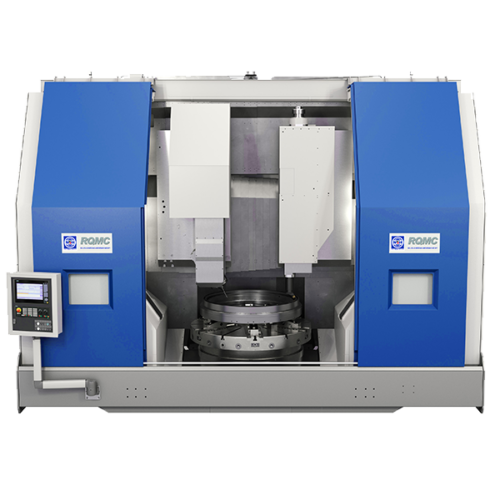

Sample of our high-precision Multitasking machines

Our News

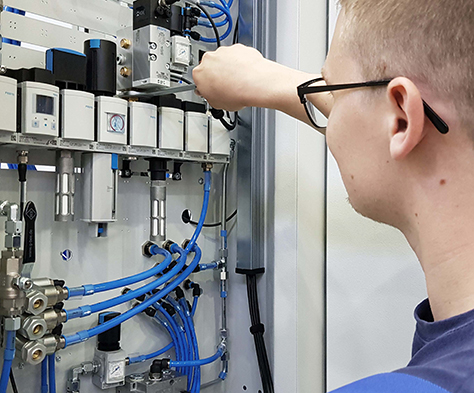

Welcome to our team!

We are delighted that a total of 13 apprentices have started their training at our…

Capital of Culture Chemnitz 2025

Our holding company NILES-SIMMONS-HEGENSCHEIDT is supporting the Capital of Culture (Kulturhauptstadt) Chemnitz 2025 with a…

Convoi Exceptionnel

Exceptional in every aspect… Exceptional quality Exceptional precision Exceptional stabilty Exceptional features Exceptional customers! We…