Complete Machining of Stator Housings for E‑Vehicles

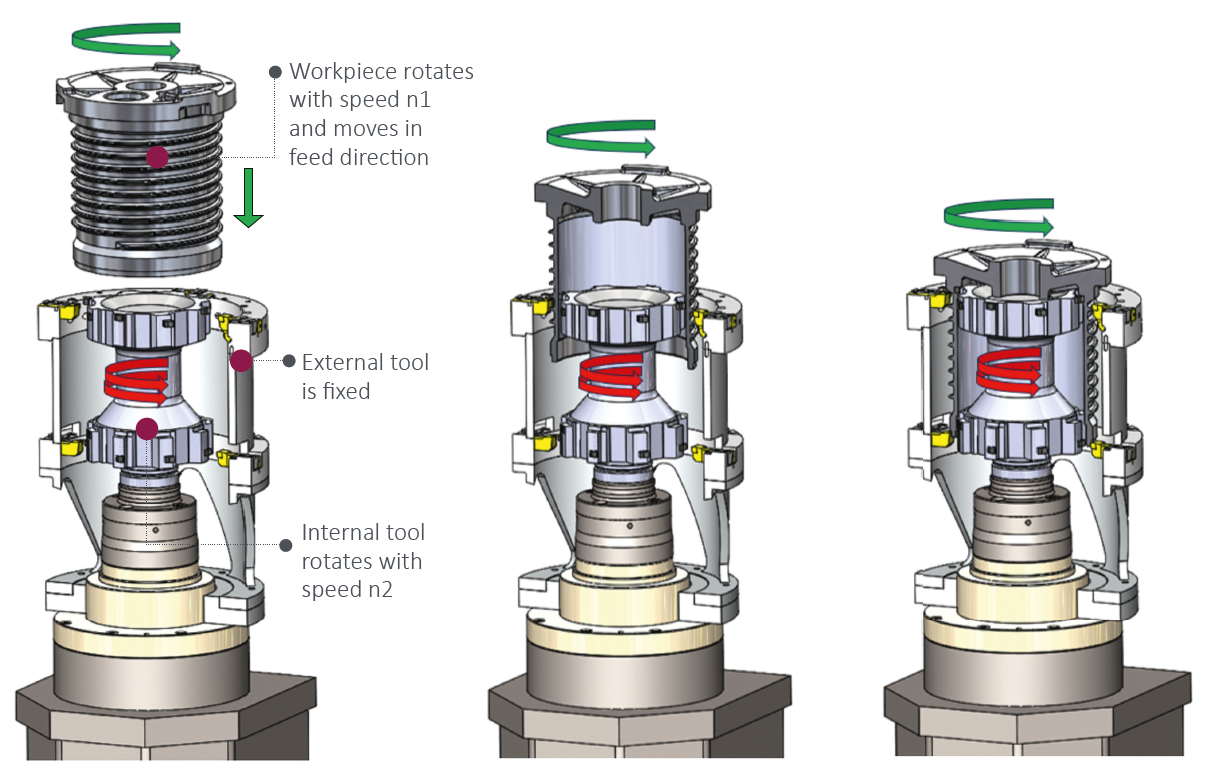

8x faster simultaneous internal-external machining

(compared to turning) thanks to a patented process

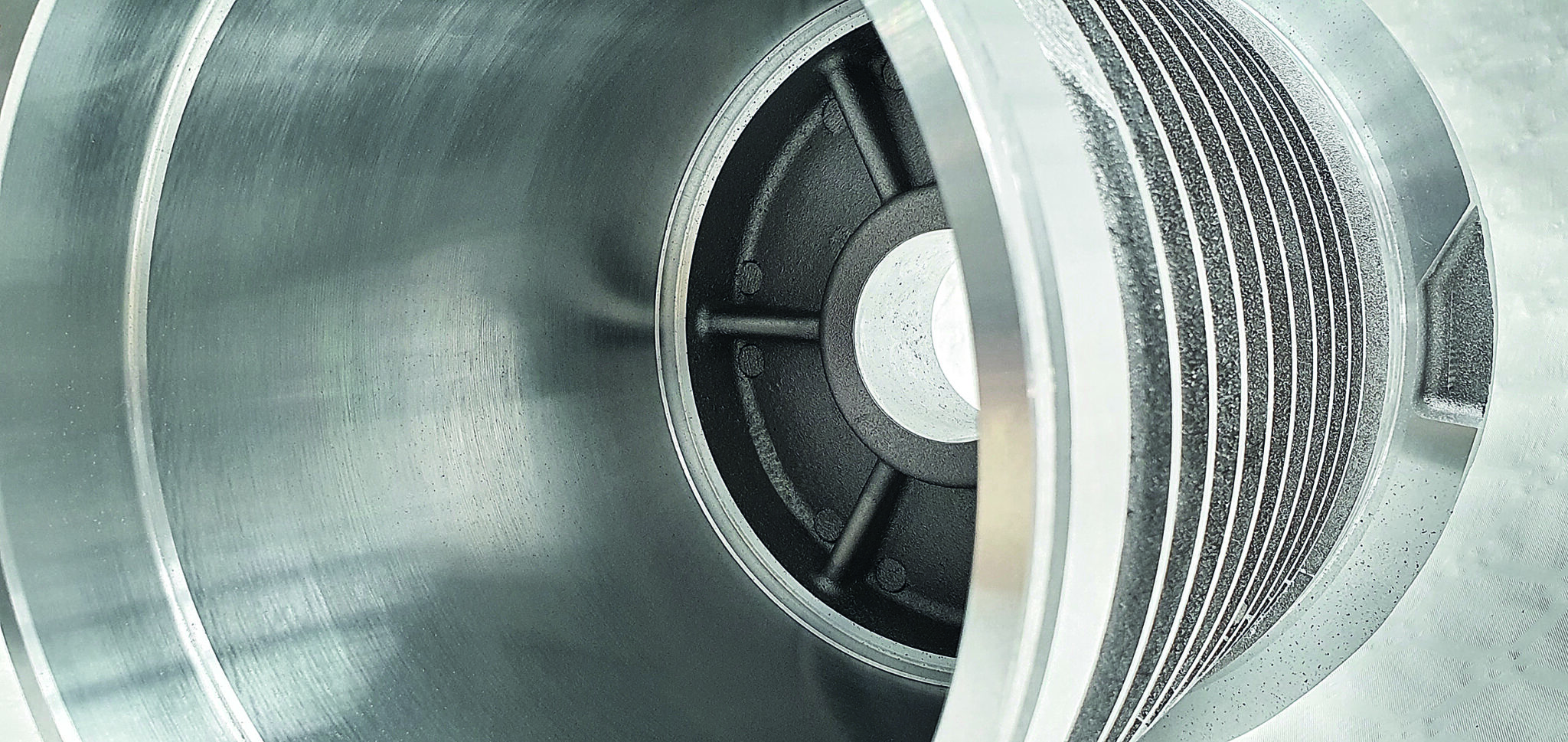

Workpiece

- Pot-shaped and tubular stator housings for electric vehicles

- Thin-walled, deformation-sensitive, vibration-sensitive workpieces

- High requirements for shape and position tolerances

- Fit tolerances in the IT 6 range

- Cylinder shapes between 20 and 30 µm

- High requirements for concentricity up to 0.05 mm

Process

(4x faster inside + 4x faster outside)*simultaneous = 8x faster

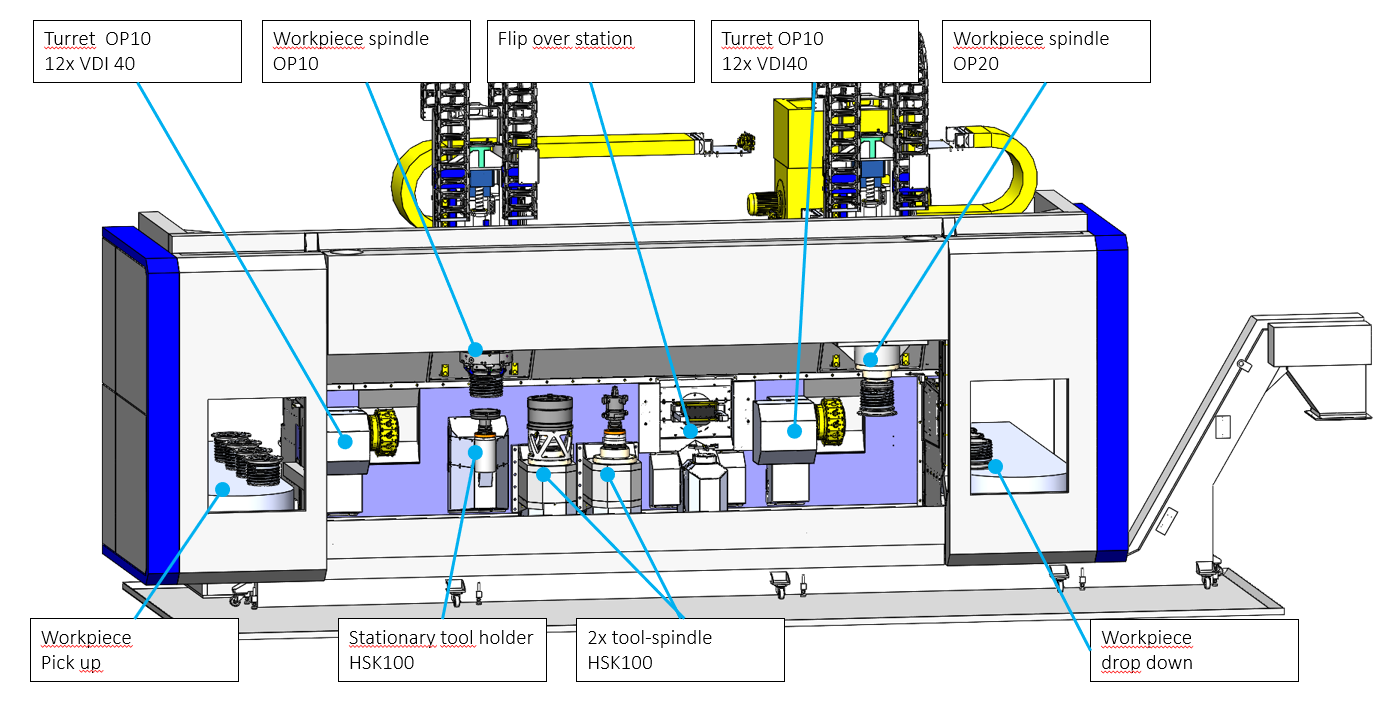

Vertical Turning Center »Statormaker«

Complete machining in 2 clamping operations

Turning, drilling, milling

2 workpieces are machined in parallel

Areas of use and application

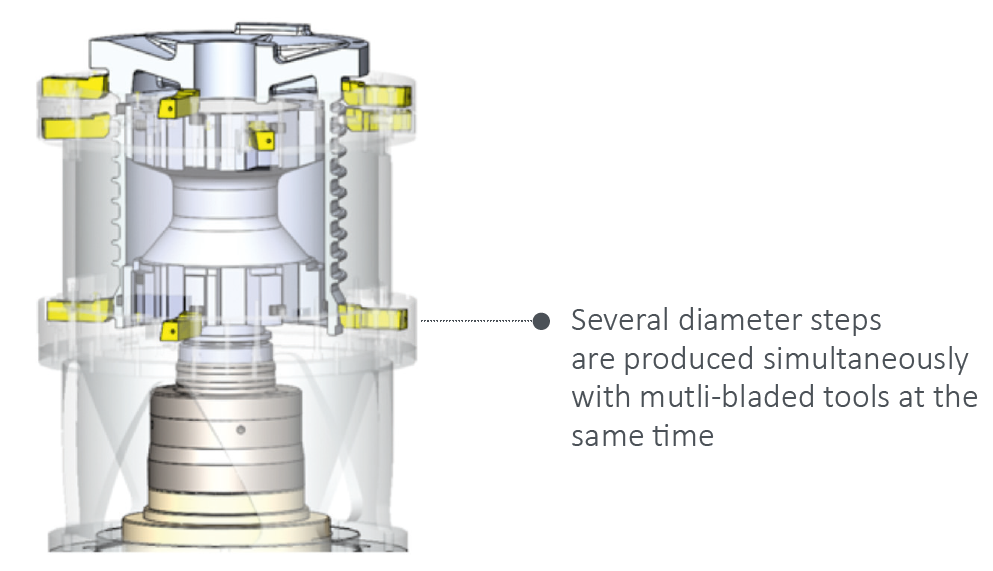

- Universal machine for all common stator housing types

- Pot-shaped and tubular, thin-walled workpieces

- Turning, drilling and milling

- Quick changeover to other workpieces