In the Aerospace

for more reliability.

The commitment could not be higher than to contribute to the reliability of the world’s largest passenger aircraft. The Turn & Mill Center Machines are in daily use in order to transport passengers to the farthest places in the world. Size and speed make the highest demands on material and manufacturing and require new standards in the machining of aircraft components, especially with regard to their reliability.

Furthermore, the focus in modern aviation is increasingly on the use of stronger and lighter materials. Upon constructional design, such highly heat-resistant materials as Titanium or Inconel are ever more in use, besides aluminium and composite materials. These factors also increase the complex demands on modern Turn & Mill Center Machines for the manufacturing of components for the aerospace industry.

Through our innovative technologies and machining concepts, we are able to meet these high demands of our customers and thus enable new standards in complete machining, from machining technologies to high-precision grinding operations.

Feedback from our customers

Success-Story with OTTO FUCHS

Our new video documentary about our successful customer relationship and the latest jointly realized project with our customer OTTO FUCHS KG is finally online.

Already at the end of summer last year we had the pleasure to look behind the scenes of the OTTO FUCHS business at the company’s site in Meinerzhagen together with the film team of our video partner Video Vision.

Some examples of workpieces

We develop Mill Turn Machines for your individual and complex workpieces. Here you can see three typical examples of workpieces for this branch.

Landing Gear

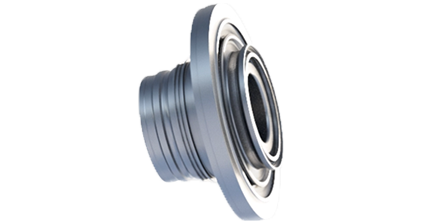

Turbine Disc

Turbine Shaft

Technologie-Highlights

Complete manufacturing of complex components: NILES-SIMMONS machine concept „CLOSED-DOOR-MACHINING“

NILES-SIMMONS developed the machining concept “CLOSED-DOOR-MACHINING to meet the ever-increasing requirements concerning the manufacturing of complex, high-precision parts and components initially for the aviation industry.

Fully automated complete machining of turbine and special shafts – NILES-SIMMONS develops the new »CENTER AXIS ALIGNMENT« process

In highly technical, innovative, and sensitive industrial sectors such as the aerospace industry or the defense and energy sectors, the demands on the production of complex components and the machining of high-strength materials are constantly increasing. In particular, the reduction of error within production processes for highly complex and cost-intensive workpieces is becoming more important with regard to the »cost-per-part« and the accuracies to be achieved.

To meet these requirements, NILES-SIMMONS has developed the new fully automated and patented machining and measuring process of »CENTER AXS ALIGNMENT« specifically for the machining of turbine shafts.