Who exhibited?

NILES-SIMMONS-HEGENSCHEIDT Group

- International machine tool group

- 7 manufacturing subsidiaries on 6 continents

- Large product portfolio

- Horizontal & vertical lathes & machining centers

- 5‑axis-milling centers

- Grinding & rolling machines

- Special machines and equipment for the railway & automotive industries

- Automation solutions

- Turnkey solutions for complete manufacturing lines & single turnkey cells

- Operating in 5 Industries:

- Machine Building

- Automotive

- Aviation

- Railway

- Tool & Die

What did you miss?

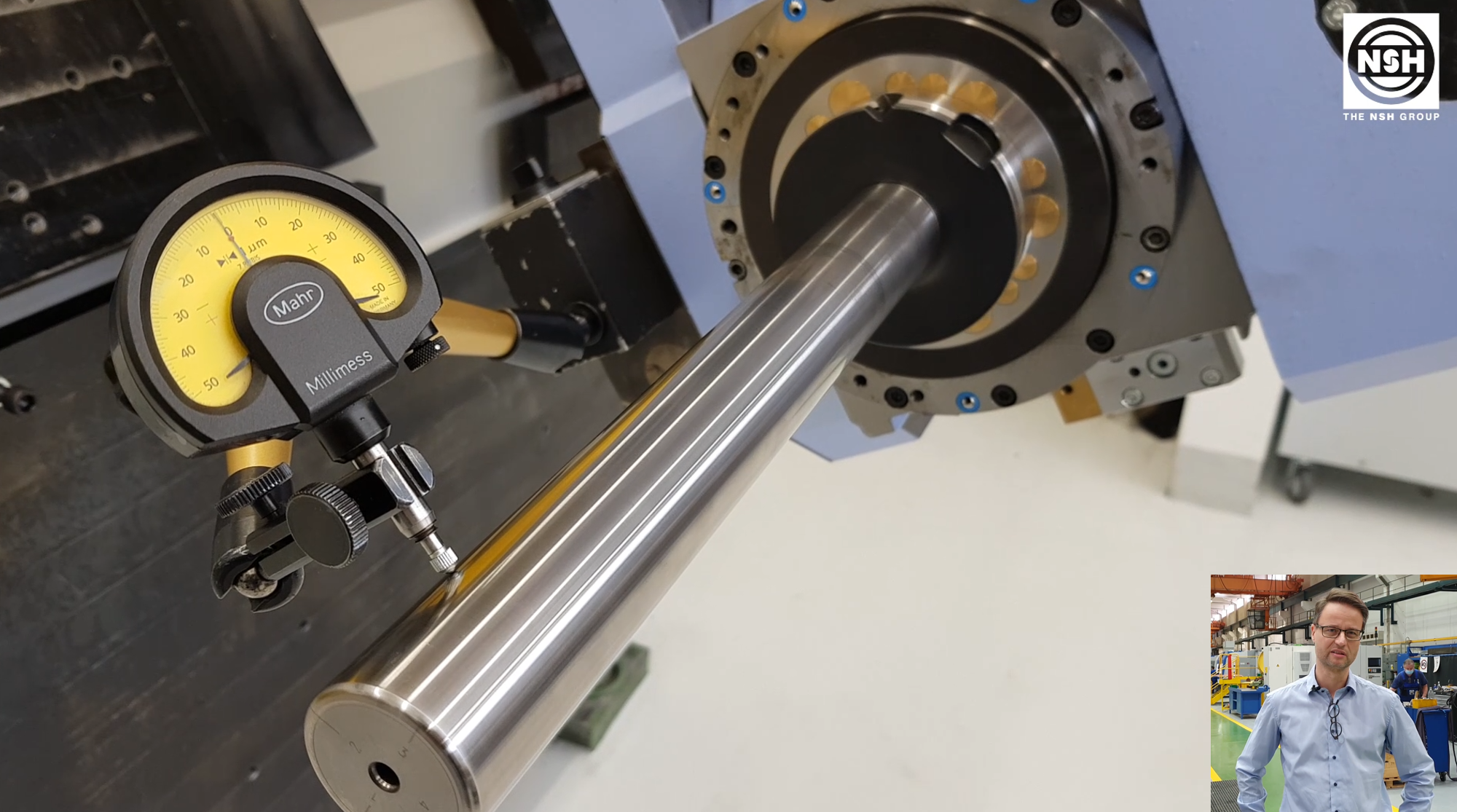

Preview 2021: New NILES-SIMMONS machine generation N40MC

- Launch of the new machine generation N40MC in Q4 2021

- Comprehensive revision and new development of our proven series N40

- Design highlights, technological variety and solutions for digitalization of machine and process

- New benchmarks in terms of machining quality, ergonomics and serviceability

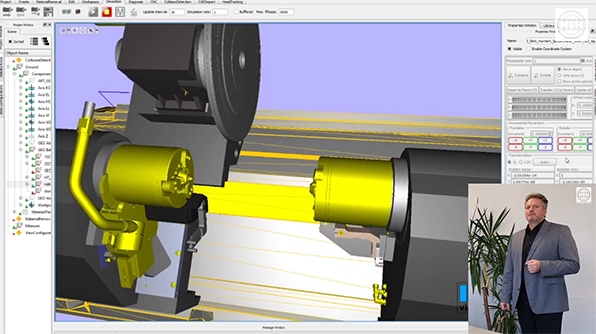

Virtual Commissioning: Efficiency, Longterm flexibility & high availability

- Development of virtual 3D-machine models & coupling with real or virtual controls

- Commissioning and comprehensive testing of functions and processes in parallel to the development- & manufacturing process

- Reduction of development & commissioning times by up to 30 – 50%

- Important service support for availabilities up to 95%

Was gab es live zu sehen?

Hier stellen wir Ihnen in Kürze die Aufzeichnungen unserer Live-Sessions zur Verfügung.

Digitalisierung von Maschine und Prozess

Thomas Koch – Leiter Produktstrategie

Daniel Peller – Steuerungsentwickler

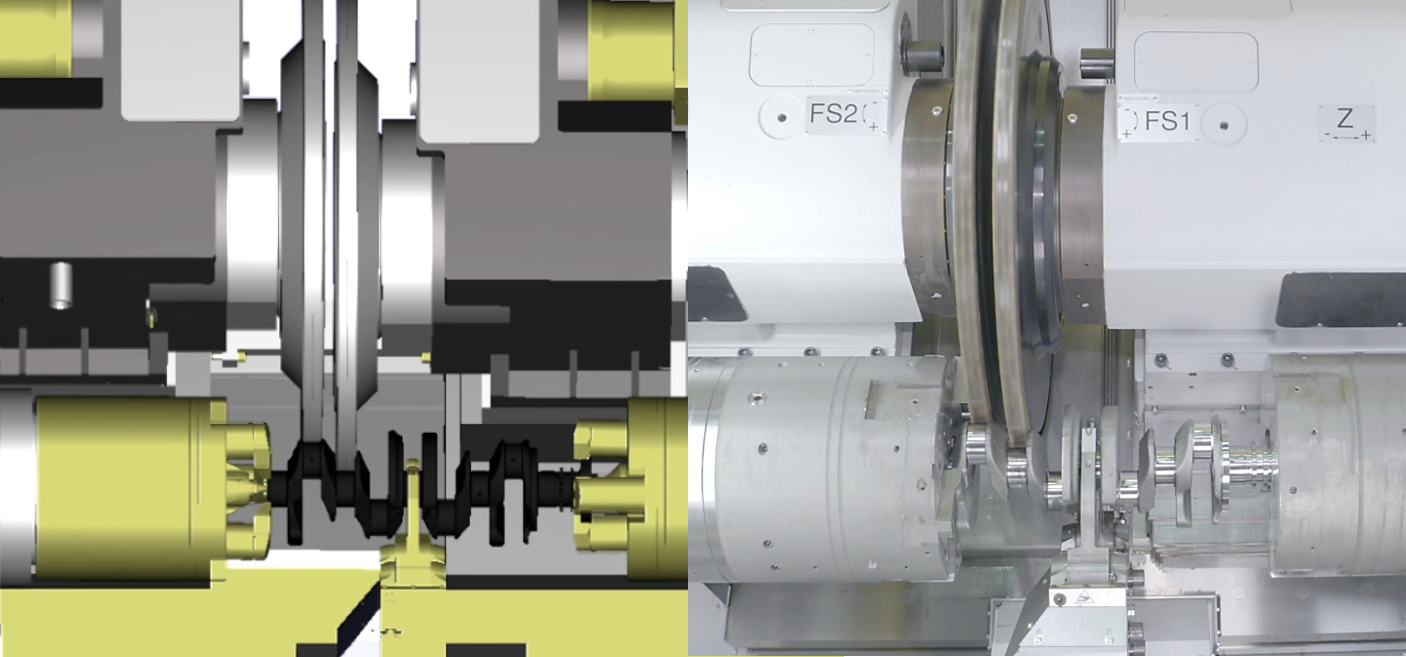

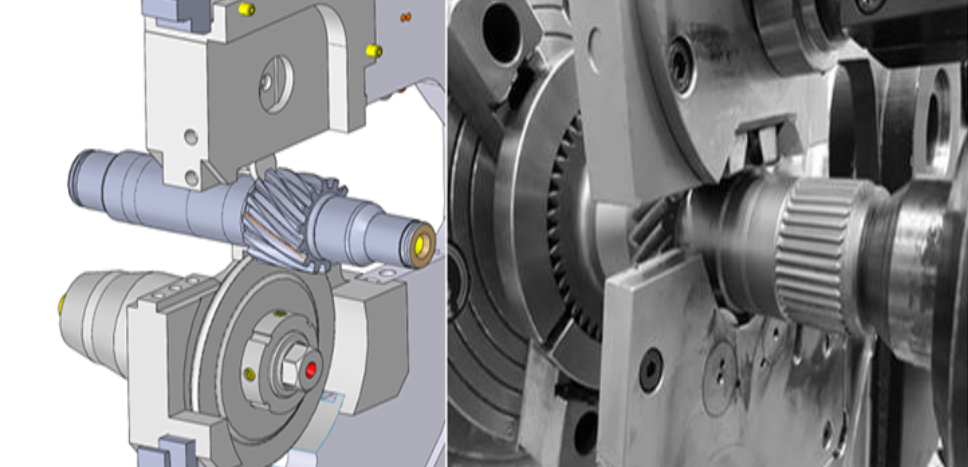

Verbindung von Produkt- und Servicequalität am Beispiel der Dreh-Fräs-Aggregate

Lutz Leonhardt – Leiter Logistik, Montage, Service

Stefan Rauh – Teamkoord. Dreh-Fräs-Aggregate

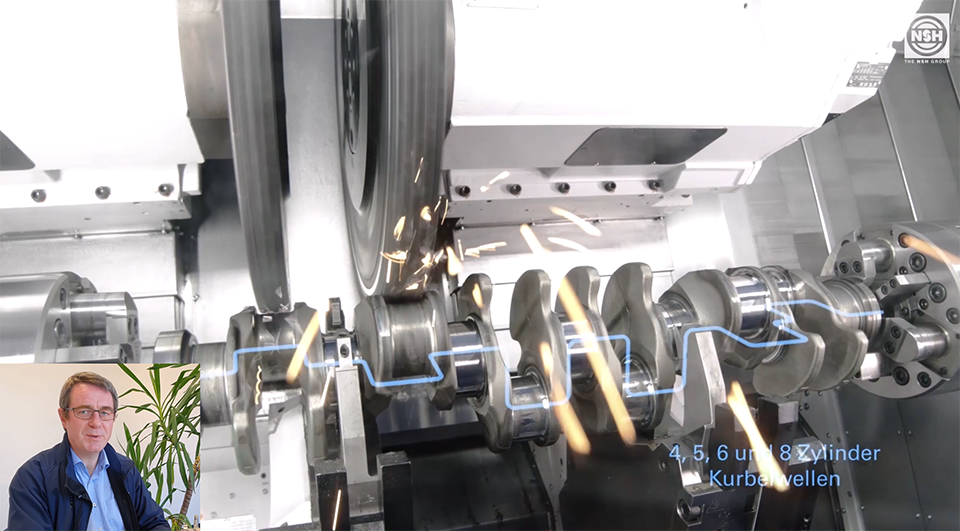

Substitution von Schleifprozessen bei der Kurbelwellenbearbeitung – NILES-SIMMONS entwickelt neue Technologie Hartfräseness

Michael Kamm, Key Account Manager Automotive

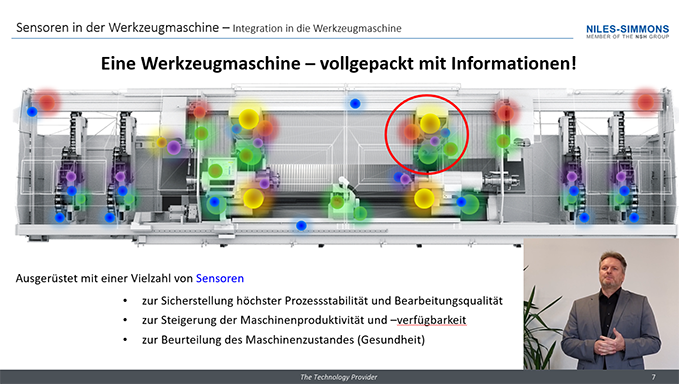

Sensorik in der Werkzeugmaschine

Thomas Koch – Leiter Produktstrategie

Live-Bearbeitung einer Schneckenwelle

Rico Löffler – Area Sales Manager

Ralph Mämecke – Anwendungstechnologe

What else?

HEGENSCHEIDT-MFD

Rolling processes – Consistent lightweight design, reduction of production costs, minimization of scrap

- Purely mechanical processes deep rolling, roller burnishing and roll straightening

- Sustainable improvement in component strength, surface quality and corrosion resistance

- Consistent lightweight design through reduced material requirements

- Reduction of production costs through dry machining and minimization of scrap

RASOMA DÖBELN

Non-Circular turning – increased transmission capability and safety

- New, efficient turning process for manufacturing of non-circular geometric shapes, for instance on shaft ends

- Production of polygonal profiles for manufacturing of shaft-hub connections

- Shaft-hub connections, which, in addition to a frictional connection, also have a form fit

- Increase torque transmission capability and thus increased safety than conventional shaft-hub connections

RASOMA DÖBELN

Automation solutions for single machines & lines

- Simple infeed & outfeed conveyors as well as gantries and multi-axis industrial robots for fully automated loading processes.

- Gantry robot series for different transport weights (smallest parts up to workpieces with max. 1.5t weight)

- Line or area gantries

- Application-specific software as well as automated & cycle-time-neutral integration of measuring & testing tasks

WEMA Glauchau

Universal grinding – complete machining & high precision

- Universal grinding machine for 4‑sided machining of all common workpiece sizes

- High efficiency and precision advantages due to machining in only one set-up by variably equipable external and internal grinding units

- Flexible response to customer-specific production processes through powerful peripheral modules

The NSH Group

Worldwide service solutions with reliable availability

- Reliable availability of original spare parts & replacement units

- Predictive machine inspections & maintenance

- Machine & control upgrades, complex retrofit & retooling projects of single machines & entire production lines

- Complete hardware & software renewal of components & assemblies

- Process and automation optimization

- Focus training courses in the areas of operation, maintenance & programming