TURN & MILL CENTER MC-SERIES

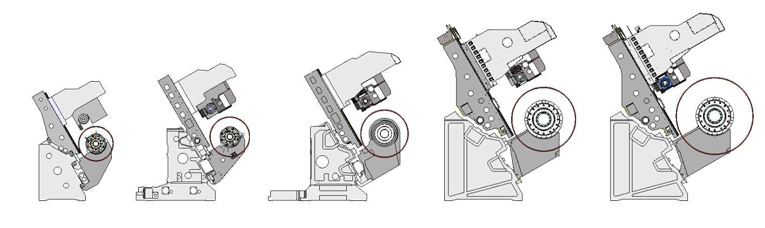

Modular system:

The NILES-SIMMONS CNC Turning and Milling Centres enable you to manage efficient, flexible, high-precision and operator-friendly complete machining of large size and rotationally symmetrical work pieces in one setup. The MC-series ranges between sizes N20 MC through N60 MC and can be configured as single slide or multi slide machines. Thanks to the modular building-block system, a variety of machining units can be added to offer utmost flexibility. Based on the MC-series lathes, efficiency of your process can be enhanced and throughput times reduced.

| N20 MC | N30 MC | N40 MC | N50 MC | N 60MC |

| Turning diameter: | ||||

| 650mm | 880 mm | 1100mm | 1250mm | 1500mm |

| Turning length: | ||||

| 1000 – 3500mm | 1500 – 4500mm | 1000 – 6000mm | 2000mm – 7500mm | 2000mm – 7500mm |

Added value:

- Utmost flexibility thanks to modular building block concept

- Variable Multi-Slide Concepts with independent technology modules

- Customized solutions for work pieces up to 7,500mm in length and 1,500mm in diameter

- Complete machining of complex work pieces by process combinations of:

- Turning, Traori Turning

- Milling / Turn-milling/ 5‑Axis milling

- Drilling / Deep Hole Drilling/ ID Machining with Boring Quill

- Gear hobbing

- Grinding

- Part Probing

- Smart Factory components for integrated production

- Process monitoring /Condition monitoring

- Automatic tool and workpiece handling

- CAD/CAM Top Solid, NX

Extension of the machining centre with technology modules:

- Duplo machine with second turning-milling-unit

- Boring Bar Slide with boring bar magazine

- Counter spindle also as pick-up spindle

- Crankshat milling unit

- Boring Quill with tool head change

- Up to three steady rest slides

- Underslide with tool turret

- Underslide with automatic tool change

- Tailstock/counter spindle on the superior slideway

- Additional NC axis in the tool for the control cutting-edge

Technology options:

- Adaptation of system boring barst o rotary milling unit

- Ejector deep hole drilling

- Burnishing- and deep rolling with force monitoring

- Gear hobbing, hobbing, skiving

- Shaping, gear shaping

- wall thickness measurement

- Workpiece measuring switching or scanning probe

- Tool measuring with switching probe or laser

- Protection Control System (PCS)

- Postprocessors Top Solid and NX