Hegenscheidt-MFD: the long history of our sister company

Wars move the economy in several ways. The change of production to armaments, the relocation of production facilities to »safer« areas, the dismantling and removal of facilities after a victory in the winner countries. In other cases, the people flee only with their knowledge. 72 years ago, in 1947, the way of Hegenscheidt company from Rabitor, Upper Silesia ended in Erkelenz, which had been conquered by the Soviet army and had became Polish. This year, the company is celebrating its 130th anniversary there. The company has made a name for itself in machine tool industry, especially with wheelset profile lathes for railways. Today the company supplies complete automatic systems for wheelset maintenance and manufacturing.

The origins of the named Hegenscheidt family comes from Altena in Westphalia, from where Carl August Wilhelm Hegenscheidt moved to Gliwice in Upper Silesia and founded a company for wire, nails and chains in 1852, where his son Wilhelm acquired his first entrepreneurial experience in this company, beofore he founded a firm for building fittings in Ratibor in 1889. The date of birth of today’s company Hegenscheidt. Wilhelm Hegenscheidt sold the company to Emil Blau in 1896 and invested in the emerging Upper Silesian heavy industry. Historically he is known as one of the co-founders of this industry.

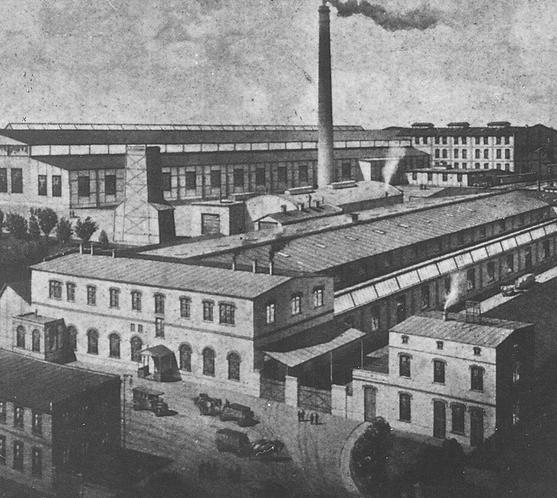

According to the information of the future owner of the company, Bernard Schondorff, Ratibor had the advantage of being an agricultural small town on the edge of the Upper Silesian industrial area, where sufficient workers could still be found – this was similar to Erkelenz, which was chosen as the location in 1947 for the same reason. Thereas well as here, according to Schondorff, employees of the core workforce were working part-time on farms as a second mainstay, which helped to ensure loyalty to the location and company. For the production of building hardware, the company increasingly produced the automatic and semi-automatic machines itself – thus the production of machine tool was established. Additional machines for mining and industry were added to the product, in which the company finally specialized. This development was particularly promoted by the railway lines, which were built with increased intensity and were sent to Russia. The acquisition of Hegenscheidt by Emil Blau, a talented technician and inventor from Austria, also played a decisive role in this. Emil Blau’s invention of a mechanical profile copying support for machining wheel profiles was produced until 1956. Complementary companies such as an axle factory, welding shop and a foundry were also acquired. The German National Railway supplied 60 percent of its requirements from Hegenscheidt, while exports provided services to the foreign markets exclusively in Eastern Europe, Russia, Belarus, Ukraine in the Balkans and China.

After the Hitler regime became more and more powerful, the orders suffered a strong interruption due to Emil Blau’s Jewish origin. He died in 1932 and his widow offered the company to Adolf Schondorff for takeover with all assets and liabilities in exchange for an life annuity and left Germany to Denmark.

At the beginning of the 1930s, engineer E.H. Adolf Schondorff took over the company, which had grown from 1200 employees in 1912 to 2500 in 1944 – but in January 1945 the end was imminent, when the Soviet army had surrounded the Silesian industrial area. Only at Ratibor was a »gate« left open to the west, through which a large part of German industry fled, which was able to make a stopover at Hegenscheidt, as Adolf Schondorff’s son, graduate engineer Bernhard Schondorff, remembered in 1964. The company had a 24-hour canteen, which was served by its own agriculture, including pig breeding; the refugees were well cared and could stay overnight.

But Hegenscheidt-Schondorff also wanted to go to the west before the conquest. With one metre of snow and 30 degrees below zero, a truck and car convoy for 28 families was put together, whitewashed for camouflage, which Bernard Schondorff led between the retreating armed forces and the advancing Red Army in the almost undisturbed no man’s land in such a way that they were »not subjected to any nuisance«. They were taken to Erfurt in Thuringia, where Schondorff received orders from the Ministry of Transport in Berlin to return to Ratibor, which had not yet been invaded, to take out the 14 finished wheel-set lathes in the factory, because they were important for the largely destroyed railway infrastructure. Schondorff had 33 railway wagons at his disposal and they even left the factory – the now liberated Czechoslovakia, through which the train had to pass, closed the border. The company was over.

Thuringia was occupied by the Americans, who, according to the Allied agreements, left it in July 1945, but who gave Hegenscheidt with a train of 80 wagons to take the company to the American zone in Munich. But there was no contact person because of the evacuation, no one went there.

After losing a large part of their customers and production facilities, the Schondorffs and employees moved further west, asking the VDW (German Association of Machine Tool Manufacturers) to look for partner companies where production could be re-esablished, if they had functional machine tools. Several companies, such as those in Düsseldorf, Karlsruhe and Gießen, were eliminated because they had been dismantled by the Western Allies. In Erkelenz they finally found the drill rig manufacturer Alfred Wirth & Co., who then built new wheelset lathes for the Hegenscheidt company, which itself operated as a sales and construction office. Initially it had to stay with this type of machine, because the other production plants in Ratibor had not moved along. Based on the experience gained in the sector of axle journal burnished technology, additionally fine rolling machines were built.

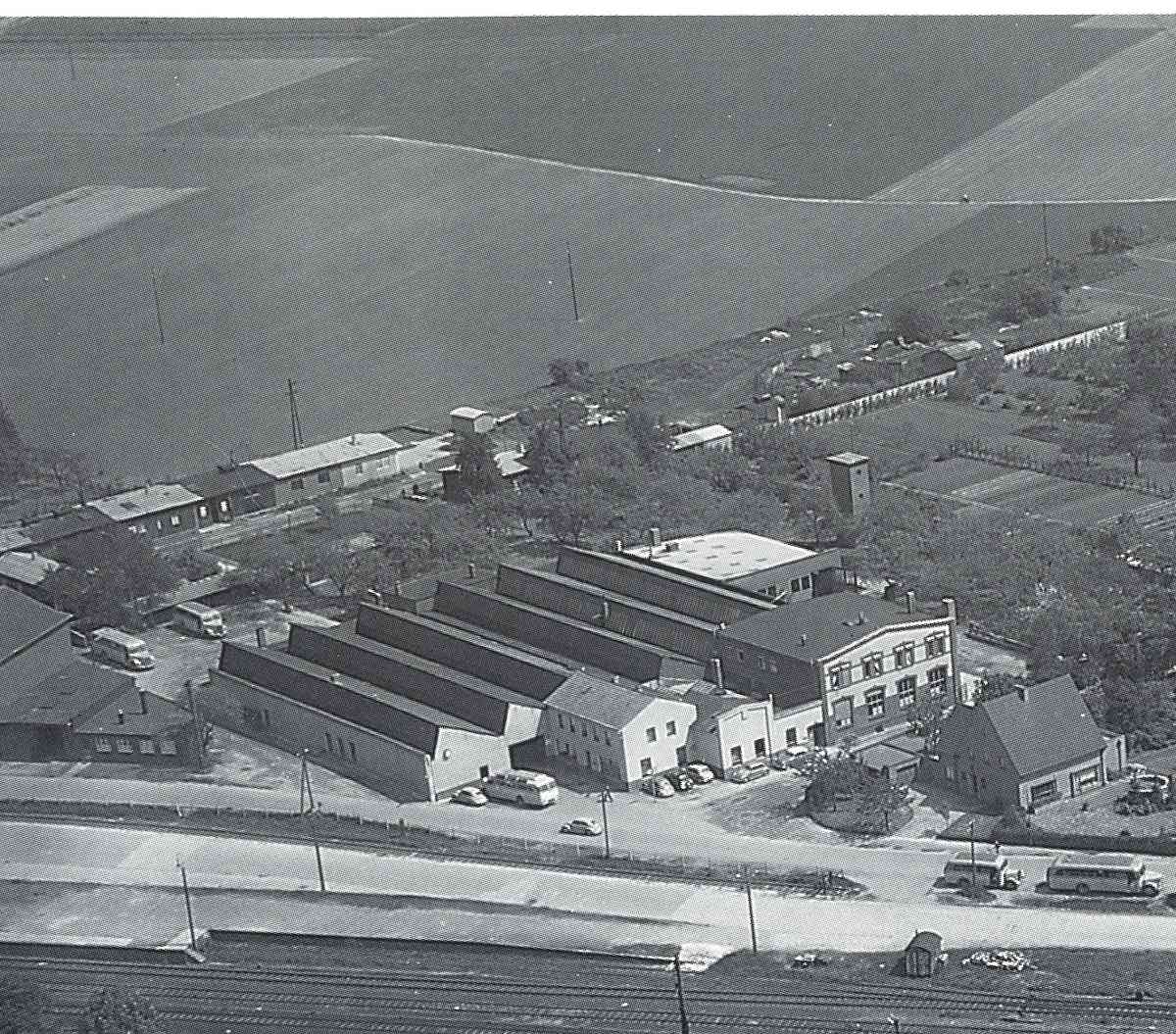

In 1964, Hegenscheidt employed 100 salaried employees and 150 workers in its own company in Neusser Straße, whereby the 15-tons wheelset lathes continued to be manufactured by the workers and by Wirth. A high percentage of the company’s own employees were engineers and designers who, among other things, developed the world’s first fully automatic wheelset lathe. Innovations were also made in the field of rolling machines, prizes were won and the company made continuous progress.

In 1995, the specialty rail equipment supplier Vossloh-AG purchased Hegenscheidt, until Professor Hans J. Naumann acquired the company in 2001. From 1970 to 1982 he was already a shareholder and managing director of Hegenscheidt, adding to it with the purchase of its machine tool companies owned in the USA and Germany. The result was the emergence of the Niles-Simmons-Hegenscheidt Group (NSH-Group). His son, John Oliver Naumann, has also been a managing director of the group for several years. The group is broadly positioned in the machine tool and mechanical engineering industry at a number of locations worldwide with production facilities, sales and service offices.