Virtual Commissioning: Efficiency, Long-term Flexibility and High Availability

Dipl.-Ing. Thomas Koch, NILES-SIMMONS Industrieanlagen GmbH

The Area of Tension

The complexity of modern machining centers increases with the number of operational functions. At the same time and in contrast to that, the available period to integrate a machine into a production line decreases continuously. This discrepancy is particularly heightened when expanding or converting existing machines, plants and manufacturing lines, whereby downtimes must be kept to a minimum. In addition, workpiece materials that are sophisticated, durable and correspondingly expensive are increasingly used, which means that intensive commissioning of machines and technology can quickly become an enormous cost factor.

Comprehensive tests of functions and processes are necessary before starting the real commissioning to manage these challenges successfully. One possibility to implement this is the virtual commissioning (VC) of machines and plants. For this purpose, we develop virtualized machine models, which represent the real system- and time behavior. If these virtual tests are successfully conducted and programmers can apply realistic machine models for verifying their developments, commissioning and development times of machines and systems can be reduced by up to 30 – 50% and a considerable increase in efficiency can be achieved.

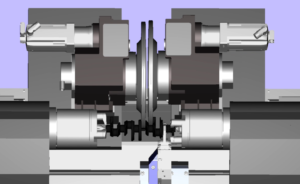

Image 1 – Virtualization of Crankshaft Machining for a Crank-Milling Machine N30CM

Functionality

Virtual Commissioning is where NILES-SIMMONS creates a virtual 3D image of one or more machines to be developed and the model is coupled with real or virtual controls. The mechanical and electrical properties of the machine is simulated as close to a 1:1 ratio as possible in real-time.

When creating a virtual machine model and connecting the model with real or virtual controls, the virtual commissioning can commence in parallel to the manufacturing process of the machine. The machine functionality as well as the mechanical behavior of the machine can be tested on the model while the software is being integrated and programmed. This enables engineers to identify any sources of error or inconsistencies and then localize and eliminate the discrepancy. Even critical machine features and applications can be modelled and intensively tested without risk.

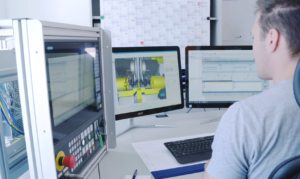

Image 2 – Tests of the virtual Machine Model at NILES-SIMMONS Industrieanlagen GmbH in Chemnitz

The tests itself can incorporate simple toggle functions, such as switching on coolant or other ancillaries, as well as following complex sequences. The modelling includes the complete machining processes or complex inter-relationships concerning material flow, robots and automated control.

By coupling several machines, manufacturing, and automation systems together, the complete manufacturing process can be simulated The simulations could model individual manufacturing cells, such as the combination of a milling machine, a measuring machine and a part handling system for instance, or they can also represent complete production lines. During the testing phase, both the processes for measuring and transferring quality and dimensional corrections to the machine and all the required alterations to the production control processes are identified. The program is optimised with the help of models that are subsequently transferred to the real system.

Image 3 – Virtual Simulation of a Complete Machining Process and Transfer to the real System

Benefits

At NILES-SIMMONS, we understand this tool as a valuable enhancement of our development process. Beside the designing abilities, we also use virtual machine models for analyzing equipment failures and opportunities for our products and services. In addition to the significant reduction in commissioning time, especially directly at the customer’s site, costs due to rework or expensive material usage for tests can be reduced drastically. Furthermore, the reliability of the systems can be increased, assisting us in our aims to guarantee machine uptimes of up to 95%.

From the customer’s point of view, another advantage of the virtual machine model is that they are highly beneficial throughout the entire life of the machines. In an agile production line, machining centers have to cope with constant machining adaptions. By using virtual models, customers can rebuild entire production lines or add only individual functionalities to the production line. Downtimes, retooling- & reorganization periods, and associated risks, are reduced to a minimum and customers can easily test new processes with little cost commitment. Virtual machine models enable optimization of the entire production planning process throughout the entire life cycle of a machine tool.

The time and cost advantages are obvious when integrating pre-tested systems. For this reason, the provision of virtual commissioning and the associated possibility of acquiring the resulting digital models is increasingly becoming key criteria. This is especially the case in the context of investment decisions made by customers investing in high-quality machine tools.

DOWNLOAD

Download Whitepaper as PDF

If you have any questions, please contact us:

SALES – TEAM

NILES-SIMMONS Industrieanlagen GmbH

Tel.: +49 371 – 802 333

Mail: sales.nsi@nshgroup.com